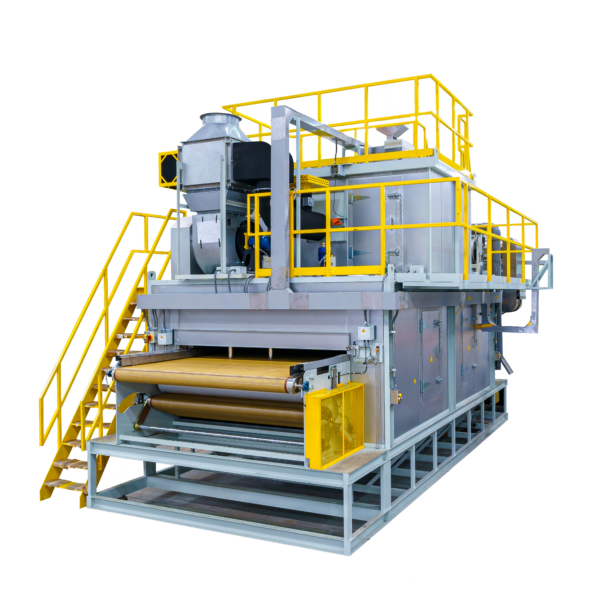

Internal Bake Oven

- Can Making Machinery

Designed for uniform air flow and temperature distribution, the ARC Pacific Internal Bake Oven cures both the interior and exterior of the can efficiently while minimizing gas consumption.

Key Benefits

Efficiently raising the cans to the required thermal profile, the ARC Pacific Internal Bake Oven (IBO) cures both cans and bottles. Utilizing both dynamic exhaust air flow balance and VFD recirculation fans that adapt to real-time production conditions, the IBO maximizes process efficiency. Combining this with ARC Pacific’s 6-inch insulated wall technology helps the Oven retain heat efficiently while also minimizing overall gas consumption. The 2-inch external safety cool walls offer safer conditions for operators. The Oven was designed with sustainability in mind, reducing overall operational Greenhouse Gas Emissions through minimized gas and electrical consumption

The IBO is the final baking stage cans undergo to cure both the freshly applied internal spray and the semi cured decoration. To achieve this the Oven is fitted with blowers featuring superior nozzle technology that efficiently transfer heat onto the cans properly curing them and providing advanced can stability. All blowers are are equipped with VFDs to help optimize air flow control and lower energy usage. Height requirements for can size changes can be quickly and efficiently achieved by the automatic nozzle height adjustment which is controlled via the HMI.

The Oven is equipped with a more robust monitoring system that has been upgraded to support highly efficient and safe operations. These monitoring systems track real-time machine pressures, perform dynamic balancing and help optimize gas efficiency, allowing for a high level of process control. The Exhaust Orifice Monitor measures the amount of air exiting the Oven in real-time, so operators can control air flow balance and exhaust rates, ensuring all operations adhere to EHS guidelines while also minimizing gas consumption. The entrance and exit exhaust hoods capture escaped heated air helping to control plant temperatures for safer working conditions. The Oven is fitted with side walkways, stairs and handrails which allow for easier and safer maintenance to the burner box.